SERVICE

Through our auditing options, we propose to evaluate the potential savings of

organizational improvement on your workshop, production line or stand alone

work stations:

* By measuring the assembly time in timing or using predetermined time base,

* By the calculation of the balance loss,

* By simulation of combinations, masked activities, transport reduction ...

We are convinced that the improvement of the working conditions is a function

inseparable from the Industrial Engineering office.

Our firm master the methods of measurement of the European Standards in the

assessment of the pain on work stations.

Training in industrial engineering is our historic job.

Our trainers are available to evaluate and discuss about the most suited training

modules that can meet the need on your next industrialization projects.

Last projects

Last training

In Europe,

Audit on an injection plastic moulding machine.

In cooperation with the Moulding Departement of

our Portuguese customer, we succeed to divide by

4 the time needed for changeover with a final

investment under 30 k USD.

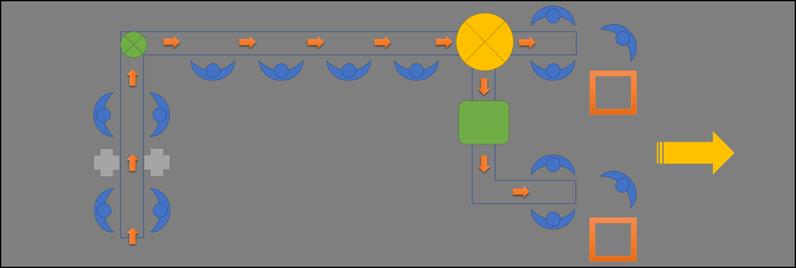

In Asia,

Simulate and optimize each steps of the assembly

process on a new product.

We are not allowed to talk about the results.

In Europe,

Training session in assembly time measurement and

balance loss reduction with a group of 6 Industrial

Engineers of a French Automotive OEM during 5

days. Now, they know how to simulate, calculate

and optimize the Labour Time in respect to the

Universal rules of time calculation.